| Availability: | |

|---|---|

| Quantity: | |

TR-B-221118

Trumony

Trumony221118

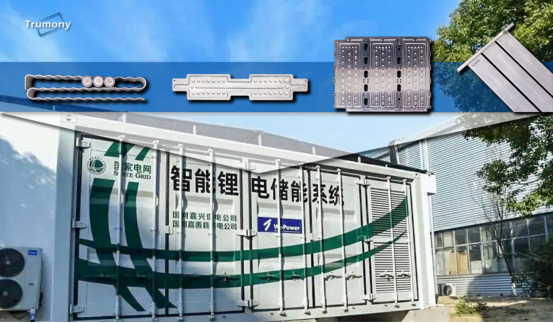

Energy storage system liquid cooling plate battery pack heat dissipation

Liquid-cooled heat transfer solutions actively provide temperature management for battery cell modules, and liquid heat transfer improves battery temperature uniformity compared to air-cooled cooling

The use of liquid cooling for uniform and targeted heating and cooling of the battery cells ensures an optimal temperature environment in confined spaces, better management of overall battery life and health, and greater certainty of system availability and efficiency as the battery can be charged and discharged to its full potential throughout the life of the ESS.

Batteries can be charged and discharged to their full potential throughout the life cycle of the ESS, resulting in increased certainty of system availability and efficiency.

For the heat exchange needs of energy storage battery pack from power generation side and consumption side, which include home energy storage system(HESS), industrial and commercial energy storage system, wind and solar energy storage integration, one-stop micro-grid energy storage and other application scenarios. Our project team will provide liquid cooling plate structure design, thermal interface material selection, pipeline layout, water cooler selection and other supporting services according to the actual requirements of customers, which can be space arrangement inside the ESS container, cell parameters, temperature difference, pressure drop, pressure resistance, etc. Brazed cold plates, machined cold plates, serpentine tubes, separated tray, integrated tray and so on can be the end-product forms.

Four types of water cooling plate we made

1) Stamping cooling plate

2) Serpentine tube

3) Extruded tube with manifold

4) Roll bond cooling plate

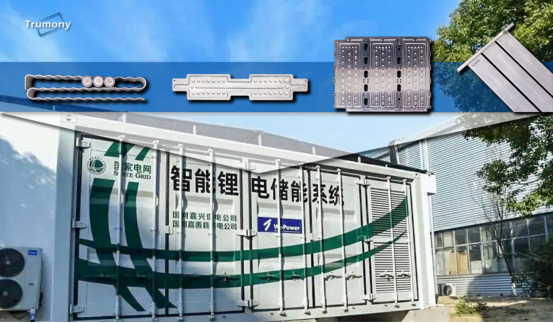

Energy storage system liquid cooling plate battery pack heat dissipation

Liquid-cooled heat transfer solutions actively provide temperature management for battery cell modules, and liquid heat transfer improves battery temperature uniformity compared to air-cooled cooling

The use of liquid cooling for uniform and targeted heating and cooling of the battery cells ensures an optimal temperature environment in confined spaces, better management of overall battery life and health, and greater certainty of system availability and efficiency as the battery can be charged and discharged to its full potential throughout the life of the ESS.

Batteries can be charged and discharged to their full potential throughout the life cycle of the ESS, resulting in increased certainty of system availability and efficiency.

For the heat exchange needs of energy storage battery pack from power generation side and consumption side, which include home energy storage system(HESS), industrial and commercial energy storage system, wind and solar energy storage integration, one-stop micro-grid energy storage and other application scenarios. Our project team will provide liquid cooling plate structure design, thermal interface material selection, pipeline layout, water cooler selection and other supporting services according to the actual requirements of customers, which can be space arrangement inside the ESS container, cell parameters, temperature difference, pressure drop, pressure resistance, etc. Brazed cold plates, machined cold plates, serpentine tubes, separated tray, integrated tray and so on can be the end-product forms.

Four types of water cooling plate we made

1) Stamping cooling plate

2) Serpentine tube

3) Extruded tube with manifold

4) Roll bond cooling plate